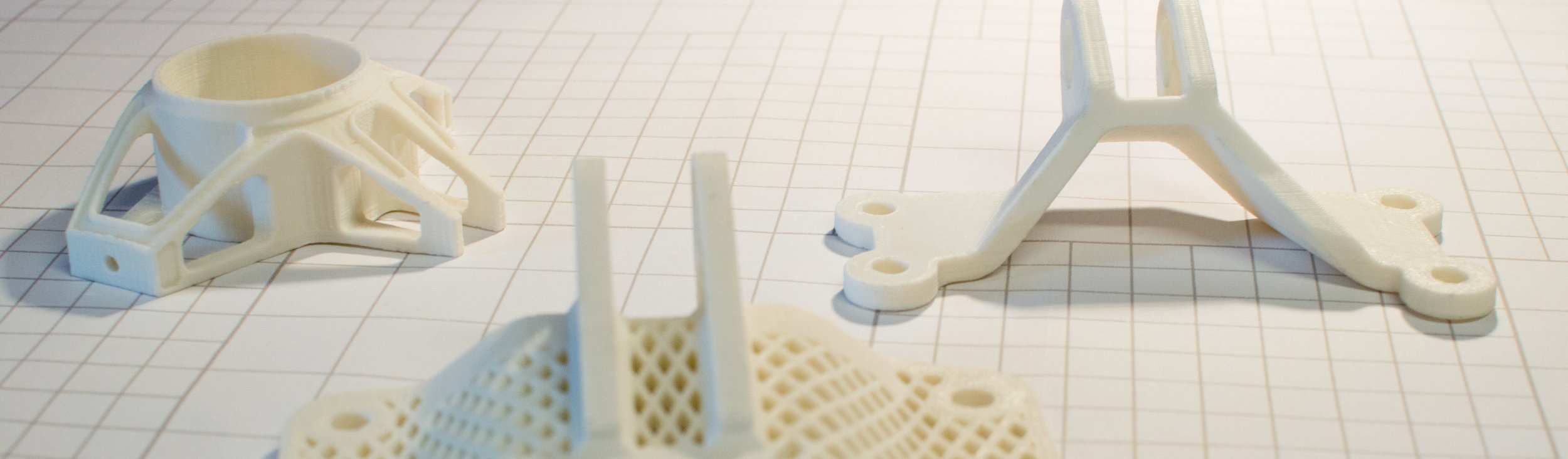

Functional Prototypes

Functional prototyping allows us to investigate how a product or part will perform, before diving into production processes which can be time consuming and costly. In order to minimise the impact (and cost) of mistakes on the final product, it’s best to fix errors and make alterations early on in the design process. Using functional prototypes to do this allows designers to get products to market more quickly and at lower cost.

We can produce prototypes using a range of different 3D printing technologies:

Our FDM printers create tough, high-performance prototypes. They can produce models in ABS, ABS Plus (Stratasys), and PLA, which means that the functionality of parts can be thoroughly tested.

Our PolyJet technology produces highly accurate, realistic prototypes, complete with clear components. We can produce models at a resolution of 16 microns, which means we can create prototypes that match the look and feel of your final product precisely. End-use features, such as threads, snap-fits etc., can also be produced accurately using PolyJet.

WHAT FOR?

Our prototypes can be used to test form, fit & function. They will accurately represent your end product's performance, allowing you to verify designs quickly and easily.

If you’re designing a piece to fit with another piece (say, for illustration’s sake, a socket for a custom plug), we can create surrogate parts to aid the design process. These parts would fill the physical space that the ‘other’ piece/s will occupy within the final product. This may take the form of an engine component within an assembly, or bottle prototypes to investigate packaging requirements, for example. These more basic parts can be prototyped at low cost, and can help to make design decisions more accurate.

'Proof of concept' models can allow you to explore a whole range of design concepts quickly and inexpensively. Ultimately, this streamlines the product development process.

Models created using our rapid prototyping technology can be used as masters for vacuum forming applications.