Medical & Dental

In the medical and dental sectors, 3D printing and additive manufacturing are quickly becoming standard practise for applications such as surgical planning, and the creation of surgical stents and anatomical models.

As scanning technologies are becoming ubiquitous in hospitals, clinics and surgeries across the UK, the use of digital design (and its associated fabrication techniques) is increasing in tandem.

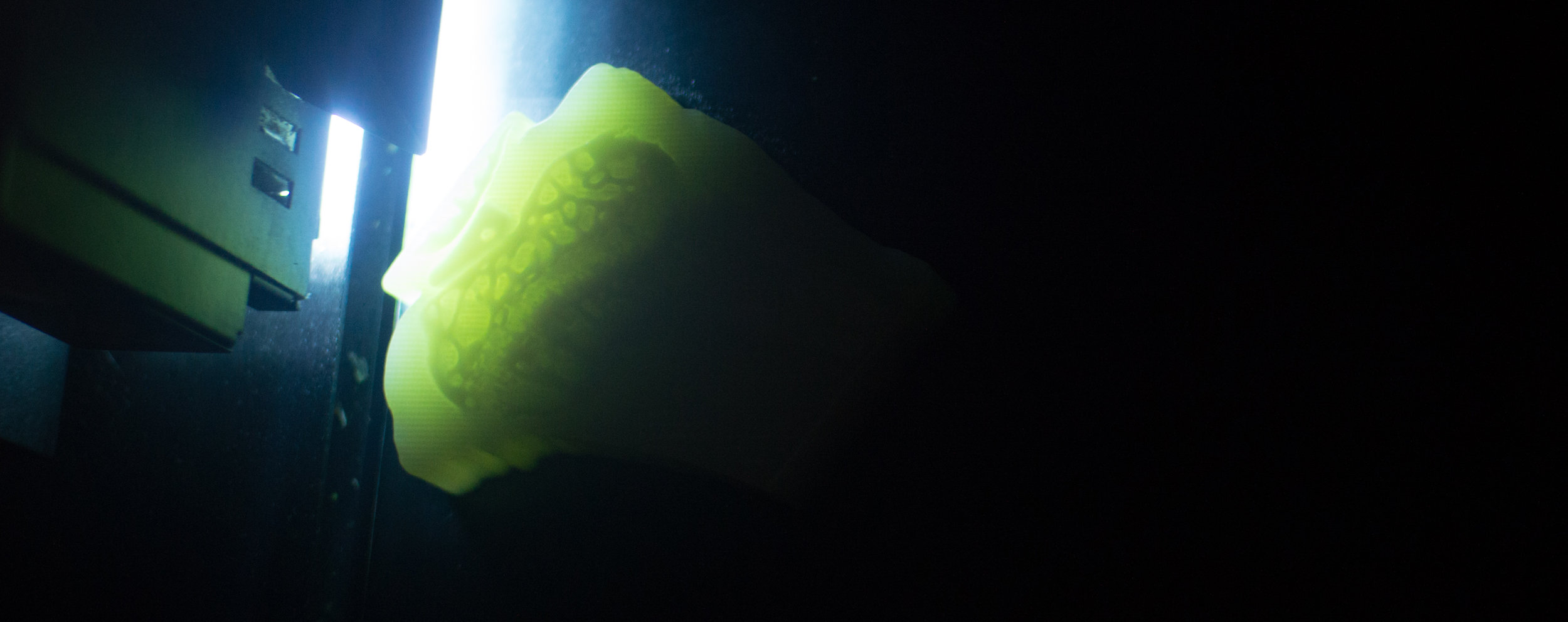

Data from ultrasound, CT and MRI scans can be extrapolated to create 3D models (of bone, soft tissue, skin etc.) which can be 3D printed as anatomically accurate reference models for use in surgical planning. Prints made with glass-clear PolyJet material can also be useful during surgery because of their transparent quality.

Typical Model Uses

- Visual reference in the operating theatre

- Templates for assistance in plate manipulation

- Surgery rehearsal

- Illustration of procedures to patients

- Surgical cutting guides (MED 610 - see Bio-Compatible Materials)

Potential Benefits

- Reduction in theatre time

- Shorter surgery times reduce risk of infection and speed up recovery

- Improved surgical results

- Assisted clinical decision making

Biocompatible Materials

We can print in MED610 (Material Safety Data Sheet) - a bio-compatible, rigid & translucent material (suitable for skin contact for more than 30 days and short term mucosal-membrane contact for up to 24 hours). This material is medically approved with regard to Irritation, Cytotoxicity, Genotoxicity, Delayed Type Hypersensitivity and USP Plastic Class IV in accordance with ISO 10993-1: 2009, Biological evaluation of medical devices-Part 1: Evaluation and Testing within a risk management process. Common applications of this material include surgical stents/guides, delivery trays, and hearing aids

STEP 3D implements a strict data handling policy to ensure privacy and anonymity.